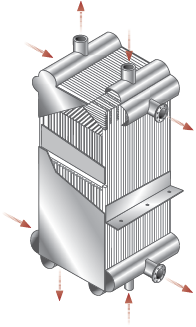

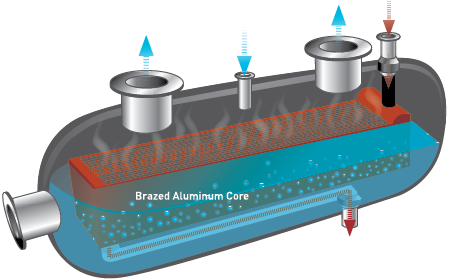

Our PFK designs use a specially configured brazed aluminum exchanger core in a vaporizing fluid bath to achieve a very high heat transfer coefficient, which far outperforms shell-and-tube and thermosiphon brazed aluminum exchangers with head drums. Kettles can be made of carbon steel, low-temperature CS, stainless or aluminum. The aluminum option allows PFK applications to be smaller and more cost effective than ever.

- Close temperature approaches increase throughput and save power and operating costs

- Smaller vessel size reduces liquid inventory, insulation, plot-plans and support structure, thus minimizing installation costs

- Multi-stream capabilities enables several duties per shell and design eliminates leaky mechanical joints

- Sheet-and-tube may be converted to PFK in the field with minimal effort